The Monash Centre for Additive Manufacturing takes fundamental research from a broad range of disciplines and applies them to manufacturing challenges.

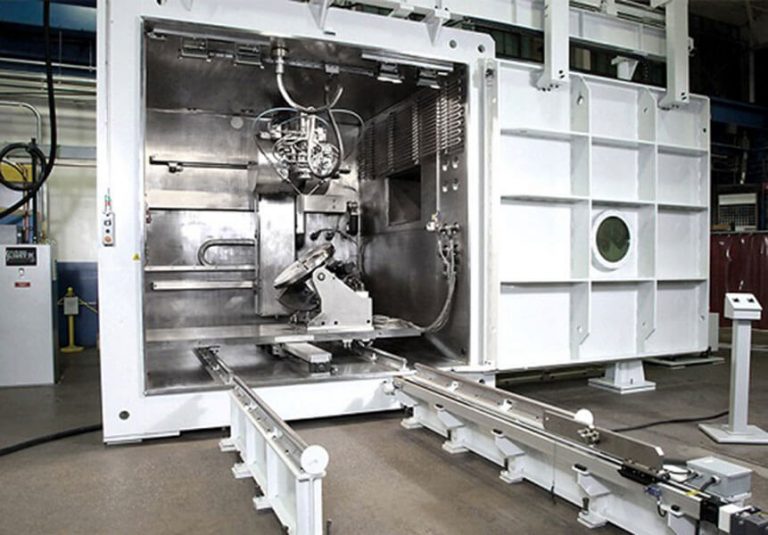

Hot Isostatic Press (HIP) - High temperature & pressure heat treatment.Direct Laser Deposition (DLD, DLF) - CNC controlled blown powder direct deposition of metals.Selective laser melting (SLM, 3D Printing) - High resolution powder bed laser melted metallic powders.MCAM's capabilites are delivered through various manufacturing technologies and software, predominantly in additive manufacturing (3D printing) of metallic alloys. Design new processes to reduce manufacturing waste.Produce new materials with improved balanced properties to achieve higher fuel efficiency and performance.Manufacture new designs and complex geometries.Our global aerospace industry partnerships are profiting from their relationship with us, as we:

The Monash Centre for Additive Manufacturing takes the most recent discoveries in alloy and metallurgical science and explore ways to apply them in real world applications – working with partners who need stronger, lighter, more cost effective components. These disciplines include material science, alloy design and processing, surface engineering, corrosion and hybrid materials. The purpose of the Monash Centre for Additive Manufacturing (MCAM) is to take fundamental research from a broad range of disciplines and apply them to manufacturing challenges.

0 kommentar(er)

0 kommentar(er)